Una batería hecha de sal de mesa y agua: ¿la revolución del almacenamiento de energía?

Mauro Mereu, 31-May-2023

© Innovation Origins

Sostenibilidad: La tecnología de batería de AQUABATTERY puede almacenar energía de forma segura utilizando agua y sal de mesa. Visitamos la inauguración de su nueva planta de producción.

Un tanque, gran cantidad de agua y sal de mesa. Estos no son solo los ingredientes necesarios de una comida para todo el vecindario. Se usan en una batería segura y eficiente que almacena energía de los paneles solares. Sin embargo, no lo haga por si mismo: esta empresa holandesa sabe hacerlo mejor.

Fundada en 2014, AQUABATTERY desarrolló una batería que puede almacenar energía renovable en agua salada. De esta manera, el almacenamiento de energía se vuelve seguro (los iones de litio pueden quemarse cuando se sobrecalientan) mediante el uso de materiales baratos, sostenibles y no escasos, como la sal de mesa y el agua. Estas ventajas garantizan el almacenamiento a largo plazo y a gran escala de energía sostenible.

La empresa inauguró sus instalaciones en Alphen aan de Rhijn (Países Bajos) para producir los primeros módulos y suministrar las primeras baterías. AQUABATTERY, calificada como “una de las tecnologías e innovaciones revolucionarias de Europa” por el Consejo Europeo de Innovación, está trabajando para aumentar la escala del sistema. Han desarrollado un módulo de potencia de diez kW y quieren ampliarlo a 100 y 300 kW en los próximos años.

“Estoy muy feliz de haber llegado a esto”, dice con orgullo Jiajun Cen, director ejecutivo de la empresa. “Aunque nuestra idea es sencilla, la tecnología detrás de ella es bastante complicada. Pero nos aseguramos de que funcione y sea económicamente asequible. Estos fueron los principales desafíos para nosotros”.

Imitando células vivas

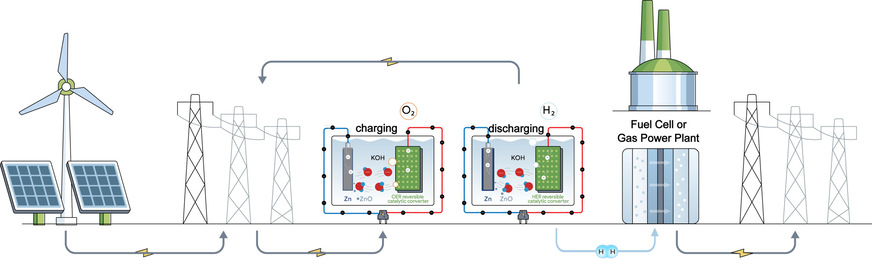

La batería estacionaria consta de dos unidades: un módulo de potencia con pilas de membranas y una unidad de almacenamiento de tanques de agua. Durante el proceso de carga, el agua salada fluye a través de membranas, donde se separa en ácido y base, cada cual terminando en un tanque separado. Cuando la batería se descarga, las dos corrientes se combinan y vuelven a atravesar la membrana, generando electricidad renovable.

“Un gradiente de sal, la energía creada por la diferencia en la concentración de sal en dos líquidos, crea una diferencia en el potencial energético”, explica Emil Goosen, fundador de AQUABATTERY. Las pilas de membranas se parecen a las membranas celulares biológicas. “El proceso imita la transferencia activa de sal, donde el agua y la sal están en equilibrio. Después de hacer ejercicio o beber mucho, se debe restablecer ese equilibrio y algunas células eliminan ciertos iones de sal del torrente sanguíneo”, explica.

Además, la solución es escalable, por lo que es posible almacenar energía durante mucho tiempo, entre ocho y 100 horas. “Al aumentar el tamaño de los embalses y el volumen de agua aumenta el tiempo de almacenamiento”, enfatiza Goosen. “Es por eso que lo hacemos flexible para cada aplicación y duración de almacenamiento necesaria, al combinar nuestro módulo de energía con depósitos de agua de diferentes tamaños”, agrega Cen.

Los dos fundadores durante la ceremonia de apertura, Jiajun Cen a la izquierda y Emil Goosen a la derecha. – © Innovation Origins

Baterías de flujo

La batería de agua y sal de mesa se incluye en la categoría de baterías eléctricas. Una batería de flujo es una batería en la que dos líquidos, separados por una membrana, experimentan reacciones electroquímicas. El sistema de AQUABATTERY consta de pilas de membranas colocadas en un contenedor de envío de 12 metros, conectadas por tuberías a los depósitos de agua. Por tanto, es muy adecuado para aplicaciones estacionarias, como el almacenamiento del exceso de energía de los parques solares o eólicos.

“En los planes para Horizon Europe, uno de los principales programas de financiación de la UE para la investigación y la innovación, las baterías de litio se mencionaron cientos de veces, mientras que las baterías de flujo se mencionaron tal vez dos veces”, dice Kees van de Kerk. Es el presidente de Flow Batteries Europe. Esta asociación reúne a diferentes partes interesadas de la UE que han hecho campaña en los últimos años para promover y resaltar el potencial de esta tecnología.

Las baterías de flujo son óptimas para dos tipos de uso. “Las aplicaciones de ciclo alto (se pueden usar durante miles de ciclos sin degradación del rendimiento) y las aplicaciones de almacenamiento prolongado son las dos más importantes. Además, el almacenamiento estacionario se está volviendo cada vez más importante y necesitamos financiación para iniciar proyectos de ampliación de la tecnología”, dice.

Solución brillante

Según Goosen, están llegando "señales positivas" de la UE sobre las estrategias energéticas. “Veo que la UE está trabajando con muchas partes diferentes para agregar más flexibilidad a un sistema energético que funciona con energía renovable”.

Al hacer realidad la transición, Cen enfatiza la "motivación intrínseca" de su equipo y su compromiso con la sustentabilidad. “Lo que más me gusta de su concepto es el medio de almacenamiento. La mayoría de las baterías de flujo usan vanadio, un metal, porque es estable, pero crear un sistema de almacenamiento solo con sal y agua es genial”, dice Van de Kerk.

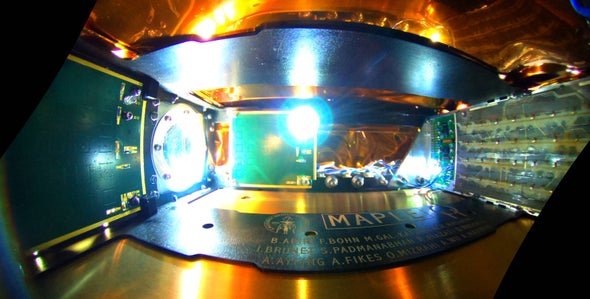

Arriba, la primera unidad de Aquabattery, abajo, el área de producción. Innovation Origins

Esfuerzos

AQUABATTERY ha estado trabajando durante diez años. Desde los primeros experimentos en una caja de garaje, se ha dedicado innumerables horas de investigación y experimentación a la idea. También hay varios prototipos en el área de producción que hacen realizable la idea.

El primer concepto fue la carga y descarga con agua dulce y salada. Luego, la empresa cambió a la solución basada en ácido actual para mejorar el rendimiento y comenzó a experimentar con diferentes pilas de membranas. En 2017, AQUABATTERY estableció su primer proyecto piloto en Green Village of Delft University of Technology. Tres años más tarde, la batería viajó a la isla de Pantelleria, Italia, y se probó en una central eléctrica local.

Esta es una tecnología radicalmente mejorada, con potencia y densidad de energía multiplicada por diez. El año pasado, el sistema fue probado en la planta de tratamiento de aguas residuales de la ciudad holandesa de Gorinchem, que utiliza electricidad renovable autogenerada a partir de un parque solar.

Para los fundadores de AQUABATTERY, lo mejor está por venir. Impulsados por la expansión de las energías renovables, pronostican que su producto se ofrecerá a diferentes usuarios. “Inicialmente, apuntamos a aplicaciones industriales y comerciales. Las empresas deberán tener paneles solares, por lo que necesitarán almacenamiento de energía a largo plazo para administrar de manera eficiente la producción y el consumo de electricidad. En el futuro, queremos instalar nuestras baterías en parques solares y eólicos como amortiguador”, concluye Cen.

https://innovationorigins.com/nl/een-ba ... gieopslag/